Diecasting is now an important process for manufacturing in Malaysia and is a major contributor to the nation’s rapid industrialization and economic growth. This method of casting precision requires forcing the molten metal into the mold cavity at extreme pressure. This results in high-quality and complicated metal products. The diecasting industry in Malaysia has grown through the years, fueled by advances in technology and the growing demand from a variety of industries, as well as strategic policies of the government. Diecasting today plays an important role in Malaysian manufacturing industry, providing sectors like automotive electronics, electronic and consumer products.

Diecasting’s history in Malaysia is as old as the middle of the 20th century as Malaysia started to become industrialized. At first, diecasting was employed to create simple metal components that were used for domestic purposes. But as the economy of Malaysia expanded and diversified and diversified, demand for more sophisticated and precise components grew. This was driven by an increase in the automobile and electronics sectors, which needed high-quality diecast components for their goods. The Malaysian government saw the power of diecasting for industrial development and began implementing policies to encourage the development of this industry, which included investment in the field of technology as well as infrastructure.

The technological advancements that have occurred are an essential factor behind the growth of diecasting in Malaysia. Utilizing computer-aided design (CAD) as well as computer-aided manufacturing (CAM) has changed production processes and allowed more precision and higher efficiency. The latest techniques for diecasting like vacuum die casting and squeeze casting are also improving the performance and longevity of the diecast components. Furthermore, advances in materials science has produced new alloys that have exceptional properties that have expanded the possibilities of use for diecasting components. This has enabled Malaysian diecasting firms to compete globally scale and meet the strict requirements of quality in international markets.

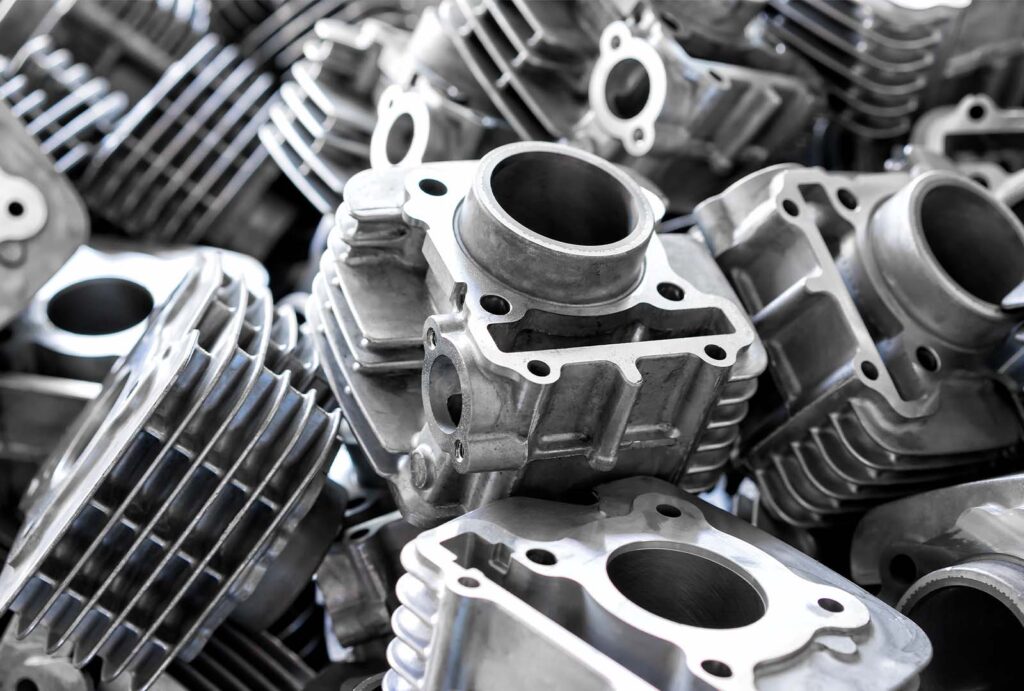

Automotive industry is among main users of Malaysia’s capabilities in diecasting. Diecast parts are crucial to manufacture various components of vehicles, such as engines blocks, transmission case as well as structural parts. The durability and precision of diecast pieces make them suitable for automotive use, in which high performance and dependability are essential. Malaysia’s strategically located location and developed infrastructure has attracted several automotive manufacturing companies, increasing the demand for components made of diecast. Diecasting’s capacity to supply this demand is what has established Malaysia as a major actor in the international auto supply chain. For more information please visit here https://www.senadiecasting.com.my/

Apart from the automotive sector, electronics is also heavily dependent on diecasting components. Diecasting can be used to create highly precise and intricate parts of electronic gadgets like connectors, housings, as well as heat sinks. The expanding market for consumer electronics which is driven by an growing the demand for laptops, smartphones and various other gadgets have created a wealth of potential to Malaysian diecasters. Utilizing advanced manufacturing methods and ensuring high-quality specifications, Malaysia has established itself as a trusted supplier of diecast products to the electronics industry. This has contributed to the reputation of Malaysia as a center for advanced manufacturing.

The future for diecasting Malaysia is looking promising. A growing trend toward lighter and efficient vehicles is likely to increase the demand for aluminum diecast components within the automobile industry. In addition, the explosive expansion of electronics is expected to continue creating potential for the diecast industry. To take advantage of these opportunities, Malaysian diecasters must continue to invest in innovation and technology and focus on increasing effectiveness and the sustainability. The government could also be a key player by assisting in research and development as well as fostering an environment that is conducive to business. In embracing these opportunities Malaysia could strengthen its position as a leading player in the diecasting business.

Diecasting, in the end, is now a crucial part of Malaysia’s manufacturing industry and supports key industries like automobiles and electronic. Diecasting’s evolution as an sector, thanks to the advancement of technology as well as strategic decisions have enabled Malaysia to be competitive at a global level. Since the demand for premium diecast products continues to rise as well, the future for diecasting in Malaysia is promising. With the right investment in new technology and maintaining the highest quality standards, Malaysian diecasters can seize many opportunities to contribute to the economic development of the nation. Diecasting’s journey in Malaysia is an example of the country’s determination to support technology and industrial development.

+ There are no comments

Add yours