The magnetic chip conveyor is a vital tool in industries dealing with metalworking or machining, as these processes often generate large quantities of shavings and waste. The efficient removal and handling of metal chips is crucial in industries such as automotive manufacturing, aerospace and machining. These sharp, tiny, and sometimes tangled parts can be difficult to handle with traditional conveyor systems. These challenges are solved by magnetic chip conveyors, which use powerful magnets that attract ferrous metals and transport them safely. This creates a safer and cleaner working environment. These conveyors help eliminate the need for manual handling, minimize material loss, and improve overall efficiency by automating the chip removal process, making them indispensable in many industrial operations.

The primary function of magnetic chip conveyors is their ability to transport ferrous materials, such as steel, cast iron, and other magnetic metals, which are often produced during machining operations. Due to their size, sharp edges and tendency to clump or tangle, these materials are difficult to transport. The magnetic chip conveyors eliminate this issue by embedding powerful magnets in the belt of the conveyor or placing them beneath its surface. Magnets create a magnetic field which attracts ferrous material and secures it to the conveyor belt. The use of this method eliminates manual handling, and reduces risk for material spillage or misalignment. The magnetic pull ensures that metal chips remain in place, making the system highly efficient in environments where precision and reliability are essential.

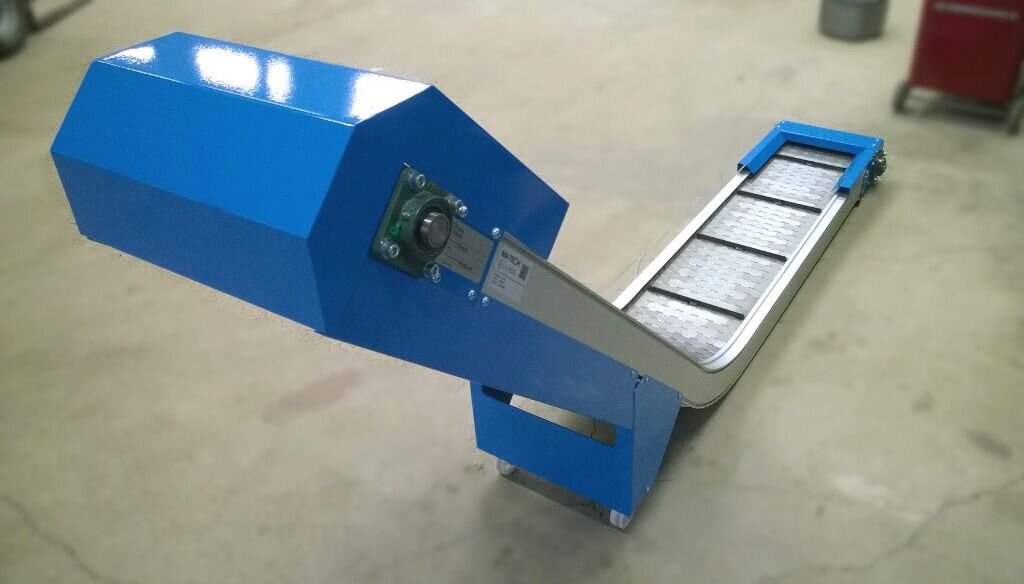

Magnetic chip conveyors are also known for their versatility. The systems are customizable to suit the needs of various industries. Whether the conveyor system needs to transport materials horizontally, vertically, or at an incline, magnetic conveyors can be designed to fit the layout of the production facility. They can also be configured to handle various chip sizes, from small metal filings to larger, bulkier metal shavings. The magnetic field strength can be changed depending on the weight and size of the material being moved. Due to this adaptability, businesses can optimize conveyor systems according to the needs of their production line. The ability to customize the system ensures that magnetic chip conveyors can be used in a wide range of metalworking environments, from small workshops to large industrial plants.

Beyond their adaptability, magnetic chip conveyors are highly efficient and help improve operational productivity. Time is a critical factor in many industries. Any interruptions to production could result in expensive delays. The traditional conveyors that rely on friction for material movement are susceptible to mechanical breakdowns and jams. The magnetic field of the chip conveyors ensures a smooth, continuous operation. Magnetic conveyors ensure that the production line runs smoothly by maintaining a constant flow of material. Additionally, because the magnetic force holds the metal chips securely, there is less need for manual intervention, reducing labor costs and further improving operational efficiency. The uninterrupted and efficient flow of materials results in a higher production rate. To generate added details please head to https://www.tecnimetal.com/project/trasportatori-magnetici/

Magnetic chip conveyors also improve workplace safety and hygiene. Metal chips are sharp and can pose a hazard to workers if they are left to accumulate on the floor or around equipment. In some industries, the presence of metal chips can also create a fire hazard, especially if they are mixed with oils or lubricants. These risks can be mitigated by magnetic chip conveyors, which collect and move the chips from working areas. It not only creates a cleaner work area, but it also keeps equipment free of debris. By keeping the work area clean, magnetic chip conveyors contribute to a safer, more efficient production process, reducing the risk of accidents, injuries, and downtime.

Another key advantage of magnetic chip conveyors is their contribution to sustainability and waste management. In industries such as metalworking and machining, recycling metal chips can provide significant cost savings, as well as environmental benefits. The magnetic chip conveyors transport collected metal waste to recycling stations where they can be processed and re-used. These conveyors reduce costs by facilitating recycling and collection of metal waste. They also support environmentally friendly practices. By recycling metal chips, you can also save valuable resources. Magnetic chip conveyors are a great way to help businesses reach their sustainability goals. They support the recycling and reusing of materials which reduces the impact of metalworking.

+ There are no comments

Add yours